|

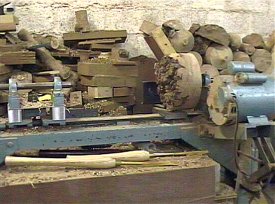

The Lathe  The Lathe |

All of the turning to date has been done on a home-made lathe which for the most part has been constructed from channel iron crome. The base is that of an old industrial sewing machine. The head and tail stock are 1" shafts which run on two pillar blocks each. The sides and cross channel of the frame are loaded with lead and this extra weight eliminates any vibration, even with natural edge bowl blanks where there is very little balance,

The only disadvantage of this lathe is that maximum turning size is approximately 11" (280mm) in diameter.

This lathe is used mainly for turning lamps where two shafts are required for mounting the timber.

|

The New Lathe before any modifications |

The new lathe is manufactured from the base of an old spindle moulding machine. This base has been striped and the table cut to allow the shaft and bearing housings to be mounted.

The inside of the machine was then modified to allow the motor to be mounted below the shaft. Both the motor and the shaft where then fitted the stepped pulley's to allow for the speed of the lathe to be set.

At this stage the mechanism that allowed the head of the spindle moulder to be raised and lowered was refitted and the chisel rest was mounted on it.

|

The New Lathe after all modifications |

Next the end of the shaft was treaded to allow the fitting of the chuck.

When all the mechanical work was completed the machine was mounted on a 300mm concret base. The concret base was designed to bring the level of the chuck up to a comfortable working height and to increase the overall weight of the machine to approximatly 1000kg. This increased weight eliminates vibration when working on large bowls.

With this new lathe bowls up to sizes of 24" (600mm) in diameter can be turned.

|